Intelligent technologies are being effectively utilized to enhance the quality, safety, and traceability of seafood and meat products. The use of intelligent tools and technologies will also support the transition to more sustainable and healthy food systems. This article describes the background of MICROORC project and introduces sustainable smart label solutions and technologies for preventing food spoilage and food waste. The development work of Oulu University of Applied Sciences (Oamk) provides insights to a novel sensing and smart label technologies.

Statistics reveal that 88 million tonnes of food produced in the EU goes to waste, with households and food processing responsible for a whopping 72% of this loss [1]. This issue has become a focal point for the European Commission too, which is dedicated to fostering environmental, social, and economic sustainability throughout the food system. Recognizing the transformative potential of microbiome-based innovations, both the EU and FAO emphasize their major potential to revolutionize food production and consumption and fighting against food waste. [2]

Addressing Food Waste reduction in Europe: development of Sustainable Solutions

The MICROORC project [3] (image 1) aims to develop novel sustainable solutions to reduce and prevent food waste. It will comprehensively evaluate and test a range of solutions, technologies, services and tools and create recommendations for policies and practices based on monitoring, utilizing, and targeting the food microbiome along the supply chain. [2] Oamk’s work in the project includes participating in the demonstration of use of smart labels for monitoring shelf-life, designing and developing new or improved solutions and identifying, sourcing, evaluating, developing, and testing suitable sensor technologies.

MICROORC will focus on three food products as an example case, chosen for their nutritional importance and as healthy protein sources: fresh chicken, smoked salmon, and plant-based meat analogues. The project will assess consumer acceptance and environmental sustainability of developed solutions at different stages of the product life cycle and propose a new regulatory framework for microbiome control in the food system. Technologies and scientific discoveries will contribute to a fair, healthy, and sustainable food system, aligning with the goals of the European Green Deal [4]. Additionally, future policy recommendations will support legislative proposals aiming to reduce net greenhouse gas emissions. [2]

Key Highlights of project Impact

Five areas are selected for the potential for predicting and extending shelf-life, reduction in food waste and fostering a sustainable food system [5]:

- Predictive analytics models incorporating microbiome information to predict shelf-life.

- Time-temperature indicators (TTIs), sensoring and smart label solutions for dynamic shelf-life labelling.

- Rapid detection assays for microbial indicators of food spoilage.

- Microbiome based protection technologies to replace synthetic chemicals and increase shelf life and safety.

- Novel packaging solutions targeting spoilage for sustainable development and increased shelf-life.

Smart Label solutions

There are several innovative smart label solutions designed for enabling dynamic shelf-life labelling, which help improve food safety, reduce waste, and enhance inventory management. Here we present some examples of these kinds of products.

Electronic Shelf Labels: These labels provide real-time updates on product information, including dynamic pricing and promotions. They sync with inventory management systems to ensure accurate stock levels and pricing [6]. These types of smart labels do not, however, usually provide any information on the status and quality of the product.

Active and Intelligent Packaging Solutions: These solutions include various technologies that monitor freshness, prevent counterfeiting, and sustain product quality. They are designed to combat excessive waste and ensure product integrity [8]. They can visually communicate the dynamic shelf life, helping to eliminate confusion over use-by and best-before dates [9].

Printed Intelligent Monitoring Labels: Companies like Ynvisible and Innoscentia have developed labels that monitor the real-time quality of food (image 2). These labels can detect spoilage before (or after) the printed expiry date, significantly improving safety and help reducing food waste [10]. These products can enable dynamic shelf-life prediction [11].

Real-time smart labels for food sensing: Smart labels equipped with sensors can provide instant temperature and other parameter readings and track the freshness of meat and seafood. These labels help ensure that products remain within safe temperature ranges throughout the supply chain, reducing spoilage and enhancing food safety. They can also be linked to dynamic shelf-life estimation. These real-time smart labels monitor and ensure the quality and safety of food products, providing valuable information to both consumers and producers.

These smart label solutions are transforming how retailers manage inventory and how consumers interact with products, making the entire food supply chain more efficient, safe and sustainable. In MICROORC project the focus is on tools and technologies that make chicken, salmon and plant-based meat analogues more sustainable and healthier.

Applications of smart labelling and sensoring in the seafood and meat industries

Time-Temperature Indicators (TTIs) are used to monitor the temperature of food products during transport and storage. For instance, they can indicate if the seafood or meat has been exposed to temperatures outside the safe range, helping to ensure freshness and safety. TTIs help in tracking the temperature conditions throughout the supply chain, ensuring that food products remain within the required temperature range to prevent spoilage and maintain quality.

The Norwegian seafood industry has successfully implemented TTIs to monitor the temperature of fish products during transportation. [12] This has significantly reduced spoilage and ensured that the seafood reaches consumers in optimal condition. The use of TTIs has also helped in maintaining the high quality of seafood.

Gas Indicators and sensors are used in packaging to detect changes in the gas composition and levels, such as increased levels of carbon dioxide, which can indicate spoilage. This helps in maintaining the quality of packaged food by providing real-time information about its freshness. Gas indicators in food packaging can detect spoilage, ensuring that consumers receive fresh and safe products. In the U.S., several meat processing companies have adopted gas indicators in their packaging to detect spoilage. [13] Companies have used these indicators to monitor the levels of gases such as ammonia, carbon dioxide and oxygen within the packaging. This has helped in ensuring that the meat remains fresh and safe for consumption, reducing the risk of foodborne illnesses.

Biosensors (image 3) are employed to detect specific pathogens or spoilage organisms in food. For example, they can identify the presence of harmful bacteria like Listeria or Salmonella, providing an additional layer of safety. Biosensors can detect contaminants and spoilage organisms, ensuring that food products are safe for consumption. These sensors can be integrated into packaging to provide continuous monitoring. The meat industry has seen success with the use of biosensors to detect pathogens in meat products. Companies have integrated biosensors into their packaging to continuously monitor for harmful bacteria like E. coli and Salmonella. [14] This has enhanced food safety and provided consumers with greater confidence in the quality of the meat products they purchase.

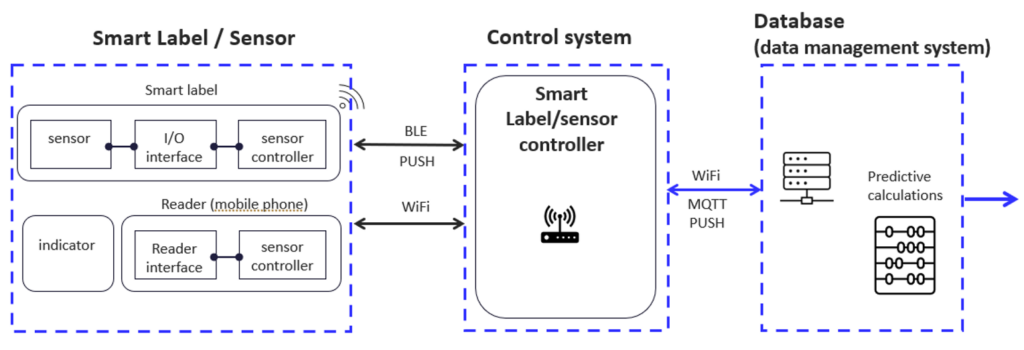

Smart label solutions can include wireless communication technologies that allow real-time monitoring of food products. This enables stakeholders to track the condition of the products throughout the supply chain and take immediate action if any issues are detected. Using wireless technologies in food packaging facilitates real-time data transmission about the product’s condition, enhancing traceability and quality control. This helps in maintaining the integrity of the food products from production to retail. Image 4 represents the wireless communication and control structure of an example smart label solution.

Seafood exporters have implemented advanced solutions that include wireless communication technologies. [15] These technologies allow real-time monitoring of the seafood’s condition during long-distance transportation. This has improved the traceability and quality control of seafood, ensuring that it arrives fresh and safe in international markets.

These applications demonstrate how intelligent technologies are already being effectively utilized to enhance the quality, safety, and traceability of seafood and meat products. The ongoing development and increasing use of these intelligent tools and technologies will also support the transition to more sustainable and healthy food systems.

Challenges and Future Directions

There are several emerging technologies in food sensing and labeling that are transforming the industry. Color-based sensors visually indicate food quality by changing color in response to specific chemical reactions, making it easy to monitor freshness and contamination. Nanotechnology-based sensors are being used to detect various components in food, enhancing sensitivity and specificity. Biosensors are integrated into packaging for real-time monitoring of spoilage and contamination.

The Internet of Things (IoT) enables smart labels in packaging, allowing real-time data collection and transmission about food conditions, improving traceability and safety. Printed sensors create flexible, low-cost, and disposable options for monitoring parameters like temperature and humidity [16] [17]. Smart labels provide interactive experiences for consumers, offering detailed product information through smartphones. These technologies offer more accurate, real-time, and user-friendly solutions for ensuring food quality and safety.

The main limitations which prevent the large-scale uptake of these products and technologies are mainly cost and scalability issues. High cost of real time smart labels limits their use only to specific cases and batch level use. Investing in research and development to create more cost-effective smart label solutions is crucial. Scaling up production requires the use of mass-manufacturable technologies and specific expertise and devices in manufacturing.

Adoption of smart label technologies also faces regulatory and consumer acceptance challenges. Different regions have varying regulations regarding food labeling and packaging. Ensuring compliance across multiple markets can be complex. Consumers may be hesitant to trust new technologies, especially when it comes to food safety. Building consumer confidence in smart labels is of great importance. We shouldn´t forget the sustainability concerns either. The environmental impact of producing and disposing of smart labels, especially those containing electronic components, is a concern we need to take seriously. Sustainable solutions, materials and manufacturing technologies are needed to address this issue. Current and future research directions are aimed at overcoming these challenges and further improving the effectiveness and feasibility of intelligent smart label solutions.

Harri Määttä

Senior Lecturer

Centre for Research and Innovation

Oulu University of Applied Sciences

MICROORC - Orchestrating Food System Microbiomes to Minimize Food Waste, started on November 1st, 2023, funded by the European Union’s Horizon Europe research and innovation program under Grant Agreement N° 101136248.

References

[1] Laaninen, T., & Calasso, M. P. (2020). Reducing food waste in the European Union [briefing]. EPRS, European Parliamentary Research Service. https://www.europarl.europa.eu/RegData/etudes/BRIE/2020/659376/EPRS_BRI%282020%29659376_EN.pdf

[2] Guiducci, M., Mincione, S., & Circelli, P. (2024). MICROORC: Microbiome for Food System Sustainability. https://www.food-hub.it/media/2024/06/14/microorc-microbioma-per-la-sostenibilita-del-sistema-alimentare/

[3] MICROORC projects website. (2024). Orchestrating food system microbiomes to minimize food waste. www.microorc.eu

[4] European Commission (2024). The European Green Deal. Striving to be the first climate-neutral continent. https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en

[5] MICROORC. (2024). Newsletter / issue n°1 / April 2024. https://www.microorc.eu/wp-content/uploads/2024/04/MICROORC-newsletter01.pdf

[6] Smart Label Solutions™. (2024). Revolutionize Retail Inventory Management with Electronic Shelf Labels. https://smartlabelsolutions.com/revolutionize-retail-inventory-management-with-electronic-shelf-labels/

[7] Ynvisible Interactive Inc. (2021). Defining the Future of Retail with User-Friendly, Sustainable and Cost-Effective E-paper-based Electronic Shelf Labels. https://www.ynvisible.com/news-inspiration/defining-the-future-of-retail-with-user-friendly-sustainable-and-cost-effective-e-paper-based-electronic-shelf-labels

[8] StartUs Insights. (2024). 10 New Smart Packaging Solutions Enhancing Product Life & Traceability. https://www.startus-insights.com/innovators-guide/new-smart-packaging-solutions/

[9] Akhila, K., Ramakanth, D., Lakshman Rao, L., Singh, S., & Gaikwad, K. (2024). Plant phytochemicals as bio-responsive compounds in smart packaging for food spoilage detection: a comprehensive review. Sustainable Food Technology, 2(4), 860−875. https://doi.org/10.1039/D4FB00072B

[10] Ynvisible. (2020). Ynvisible And Innoscentia Are Fighting Food Waste With Printed Intelligent Expiry Date Label [Press Release]. https://www.ynvisible.com/news-inspiration/ynvisible-and-innoscentia-are-fighting-food-waste-with-printed-intelligent-expiry-date-label?datasheet-popup-close=1

[11] Innoscentia. (n.d.). Unlocking true shelf life. https://www.innoscentia.com/

[12] Biegańska, M. (2017). Shelf-life monitoring of food using time-temperature indicators (TTI) for application in intelligent packaging. Polish Journal of Commodity Science, 2(51), 72−85. https://www.researchgate.net/publication/316527247_Shelf-life_monitoring_of_food_using_time-temperature_indicators_TTI_for_application_in_intelligent_packaging

[13] Norris, M. (2020). Packaging Sensor Predicts Shelf Life of Perishable Foods. Packaging World. https://www.packworld.com/home/article/21140375/packaging-sensor-predicts-shelf-life-of-perishable-foods

[14] Flauzino, J., Alves, L., Rodovalho, V., Madurro, J., & Madurro, A. (2022). Application of biosensors for detection of meat species: A short review. Food Control, 142, 109214. https://doi.org/10.1016/j.foodcont.2022.109214

[15] Hassoun, A., Cropotova, J., Trollman, H., Jagtap, S., Garcia-Garcia, G., Parra-López, C., Nirmal, N., Özogul, F., Bhat, Z., Aït-Kaddour, A., & Bono, G. (2023). Use of industry 4.0 technologies to reduce and valorize seafood waste and by-products: A narrative review on current knowledge. Current Research in Food Science, 6, 100505. https://doi.org/10.1016/j.crfs.2023.100505

[16] Määttä, H., Nissinen, M., Torniainen, N., & Tuomaala, T. (2022). Printed electronics as an enabling technology − introduction to printed electronics. Oamk Journal, (212). Oulun ammattikorkeakoulu. https://urn.fi/URN:NBN:fi-fe2022122173081

[17] PrintoCent. (2019). Introduction to Printed Intelligence. Handbook for technology training and coaching.

Vastaa

Sinun täytyy kirjautua sisään kommentoidaksesi.