This article describes the background and introduces the successful piloting execution of CoRoSect project’s insect farming automation system. Oamk’s development work provided a new multimodal sensing method, including active sensing. A novel integrated sensing method utilized also printed electronics technologies.

The CoRoSect-project (image 1), funded under Horizon 2020 and led by Maastricht University, commenced in January 2021 and successfully concluded in March 2024. The project was the first EU horizon 2020 project in the history of the Oulu University of Applied Sciences. The project aimed to create collaborative environments between humans and robots, streamlining labour-intensive tasks in insect farming production. It’s main goal was to significantly enhance the optimization and automation of small and medium-sized insect farms that breed and rear black soldier flies, mealworms, and crickets. To achieve this, CoRoSect introduced an integrated cognitive ecosystem that automates monotonous and challenging aspects of insect farming. [1]

The achievements of the CoRoSect, with 19 partners (image 2) spanning Europe, represent a groundbreaking transformation in insect farming automation. Its legacy heralds the dawn of a new era, offering the potential for significant advancements in the future of insect farming and automation. Comprehensive details about the project can be found on its website and LinkedIn pages. [2]

The main benefits and potential of insect farming are:

- Resource efficiency: Insects are remarkably efficient at their resource utilization. They require minimal land and energy to produce, making them an attractive option for sustainable food production. Unlike other feedstocks, insects can be cultivated rapidly and year-round, providing a consistent supply.

- Demand for protein: Insect farming addresses the growing demand for protein. These tiny creatures need less land and water compared with traditional livestock. They excel at converting low-quality organic waste into protein-rich products suitable for both animals and humans.

- Beyond Aquaculture: While aquaculture is a promising market, insect-derived products have broader applications. Fertilizers and biofuels are being explored as well. Insects contribute to a more diversified and sustainable economy.

- Tackling Food Waste: Food waste is a global challenge. Insect farming embodies the principles of a circular economy by utilizing organic waste to produce valuable protein. It is a profitable solution that aligns with environmental goals.

- Automation and Robotics: Human intervention remains a hurdle in insect farming. Innovative projects like CoRoSect leverage robotics to support every phase of an insect’s life cycle. CoRoSect’s emphasis on harmonious collaboration between humans and robots not only transforms insect rearing practices but also optimizes production processes, leading to improved sustainability and increased income generation.

Remarkable Achievements in Insect Farming

The CoRoSect project tackled practical challenges in insect rearing, encompassing tasks such as crate handling, environmental condition monitoring, larvae separation, and quality management. The success of the project hinged on four large-scale pilots conducted across Norway, Italy, Bulgaria, and Spain. These pilots allowed for the refinement of the CoRoSect system, which comprises a diverse array of software and hardware components with varying levels of complexity. The collaborative efforts of the consortium members, along with the cooperation of insect farms that contributed their time, space, knowledge, and insect resources, culminated in the successful fine-tuning of the CoRoSect system. [2]

I would like to thank the European Union as well as

all partners and stakeholders of CoRoSect for their enthusiasm,

commitment, and support during the past three years. Together we have been on an exciting journey to provide insect farms with next generation robotic and digital solutions. Remarkable results have been achieved. It has been an honour to serve this project as project coordinator.

Dr. Rico Möckel, Maastricht University

The results of the CoRoSect project stand at the forefront of innovation by ingeniously converting low-quality organic waste into protein-rich sustenance suitable for both humans and animals. This alignment with circular economy principles underscores its commitment to sustainable practices.

CoRoSect’s impact extends beyond mere insect rearing. By nurturing a symbiotic relationship between humans and robots, it achieved two pivotal goals:

- Revolutionizing Insect Rearing [3]

CoRoSect disrupted traditional methods by introducing novel technologies, automation and efficiency. It addresses challenges related to crate handling, environmental monitoring, larvae separation, and quality management, which leads to a more streamlined and effective insect farming process. - Enhancing Sustainability and Income Generation

CoRoSect’s innovations lead to sustainable practices that benefit the environment and society. Simultaneously, it opens avenues for income generation within the insect farming industry.

Key Highlights of CoRoSect’s Impact

Project successfully executed four pilots at insect farms. Pilots were in INVERTAPRO (Norway) [4], Italian Cricket Farm (Italy) [5], Nasekomo (Bulgaria) [6], and Entomotech (Spain) [7]. Pilots were a perfect place for informative demonstrations of the technologies and developments which were done during the project. More than 50 scientific and business players benefited from CoRoSect demonstrations.

A novel service-oriented ICPS (Integrated Cyber Physical System) was created in the project, capable of supporting more than 97% of key target task planning and real-time adaptation scenarios in insect farming. A system to classify larvae with more than 90% accuracy was developed and demonstrated. [2]

Oamk’s development work focused on the new multimodal sensing method, including active sensing. Novel integrated sensing methods utilizing conventional as well as printed electronics [8] performed well, with more than 92 % timely-significant events detection rate. The sensor system was piloted and tested on all four pilots.

Piloting produces significant benefits

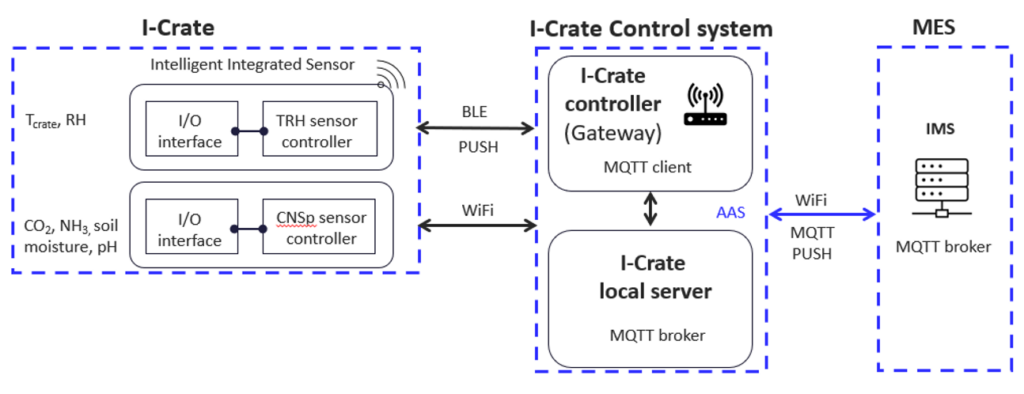

In the following section of this article, we present in more detail actions related to project piloting. Oamk’s part of the system is called I-Crate, which is used from now on to describe the Oamk’s system. I-Crate integration architecture [9] is shown in image 3.

Oamk’s contribution to the pilot execution was essentially carried out using the same protocol in each of four pilots. Preparation for the pilots began in Oulu, Finland, with the careful implementation of final functional tests for both the hardware and software of the I-Crate system (image 4). Once everything was ready, all the needed system parts and tools were carefully packed for the trip to the pilot location. This required a lot of planning and testing to make sure everything needed was at the pilot’s location.

Upon arrival at the pilot location, the first task was to unpack the system and conduct a visual inspection to ensure all components were intact and accounted for. The setup of the I-Crate system involved powering the sensors, sensor boxes, gateways, and other necessary equipment. Next, the I-Crate controller was connected to the local CoRoSect network, either via Ethernet or Wi-Fi, depending on availability. The I-Crate local server was then configured and the global CoRoSect MQTT broker address was updated in the system. Additionally, modifications to the hosts file on the connected laptop were required to enable access to the CoRoSect dashboard. Finally, the MQTT Explorer tool [10] was used to verify that the I-Crate system was fully operational and transmitting data to the CoRoSect system.

The piloting phase involved placing sensors in insect-rearing crates to measure environmental variables such as the temperature, humidity, CO2, NH3, soil moisture, and pH. In certain cases, the ambient temperature and humidity of the piloting premises were also monitored. A variety of sensors were used and compared, some were commercial components integrated into sensor boxes, while others were incorporated into custom-printed circuit boards. Comparison measurements were conducted using reference instruments to ensure accuracy. Tests were performed in accordance with the Key Performance Indicator (KPI) test protocol at specific intervals to assess system performance. Throughout the several days of piloting, system maintenance was carried out as needed. Any faults and problems were inspected and the root causes were analyzed and predicted.

When conducting pilot tests on various locations, it was essential to consider the guidelines and restrictions of the participating companies. In many cases, the scope of what could be tested on-site was unclear beforehand, and access to all areas was not always granted. As a result, tests often had to be adapted based on what was feasible and measurable at each site. Some pilot locations were already in full production, while others were more research-oriented, further influencing the nature of the tests. Additionally, the types of insects varied depending on the location, with some requiring special considerations due to their unique growth environment.

Sensor data was continuously monitored and recorded using the CoRoSect Integrated System, which incorporates an internal instance of the Grafana tool, complete with customized dashboards. Grafana leverages historical access APIs to create tailored visualizations of the collected data, enriching the presentation layer for the historical records managed and stored by the MES Information Management System (IMS) [11]. These visualizations provide a clear and intuitive view of the performance of the system over time. Image 5 illustrates the dashboard specifically designed to track and monitor the I-Crates deployed during the pilot tests.

Conclusions

CoRoSect introduced an integrated cognitive ecosystem that automates the monotonous and challenging aspects of insect farming. The results of the CoRoSect project stand at the forefront of innovation by ingeniously converting low-quality organic waste into protein-rich sustenance suitable for both humans and animals. This alignment with circular economy principles underscores its commitment to sustainable practices.

The project successfully executed four pilots at insect farms in four different countries across Europe. Pilots were a perfect place for the informative demonstrations of the technologies and developments which were done during the project. More than 50 scientific and business players benefited from CoRoSect demonstrations.

While the pilots were primarily designed for testing and demonstrating technologies, they also provided a valuable opportunity to gather insights into the industry’s specific needs and requirements. The planning, careful packing of the system, and travel involved significant time and effort, but the overall outcomes offered substantial benefits for both project execution and future developments. The pilots also facilitated collaboration with other project partners, allowing for the direct observation of their progress and the solutions they employed to overcome challenges. After each pilot, new insights were gained about measurements and obstacles, leading to system improvements and adjustments for the next phase.

Harri Määttä

Senior Lecturer

Centre for Research and Innovation

Oulu University of Applied Sciences

Niina Torniainen

Researcher

Centre for Research and Innovation

Oulu University of Applied Sciences

All articles by CoRoSect-project in Oamk Journal

References

[1] CoRoSect Project. (2021). Homepage. https://corosect.eu/

[2] Tolmačev, A. (2024). EU Project CoRoSect Comes to a Close: New Dawn for Insect Farming Practices Begins [Final Press Release]. https://corosect.eu/eu-project-corosect-comes-to-a-close-new-dawn-for-insect-farming-practices-begins/

[3] Hannula, M., Hedström, H., Määttä, H., Tuomaala, T., & Nissinen, M. (2023). Hyönteisviljelyn automatisoinnissa pörisee potentiaalia. Oamk Journal, (84). Oulun ammattikorkeakoulu. https://urn.fi/URN:NBN:fi-fe2023060151562

[4] Invertapro. (2023). Homepage. https://www.invertapro.com/en

[5] Italian Cricket Farm. (n. d.). Homepage. https://www.italiancricketfarm.com/

[6] Nasekomo. (2024). Homepage. https://nasekomo.life/

[7] Entomotech. (2024). Homepage. http://entomotech.es/

[8] Määttä, H., Nissinen, M., Torniainen, N., & Tuomaala, T. (2022). Printed electronics as an enabling technology ‒ introduction to printed electronics. Oamk Journal, (212). Oulun ammattikorkeakoulu. https://urn.fi/URN:NBN:fi-fe2022122173081

[9] CoRoSect Project. (2022). D2.4. Advanced System Architecture. https://corosect.eu/wp-content/uploads/2024/03/D2.4.-ADVANCED-SYSTEM-ARCHITECTURE.pdf

[10] MQTT Explorer. (n. d.). Homepage. https://mqtt-explorer.com/

[11] CoRoSect Project. (2023). D9.4 – Test cases for the CoRoSect ecosystem. https://corosect.eu/wp-content/uploads/2024/03/D9.4-Test-cases-for-the-CoRoSect-ecosystem.pdf

Vastaa

Sinun täytyy kirjautua sisään kommentoidaksesi.